PROCESS

- Oil Drawn Processing

- Precision Rolling

- Welded Stainless Steel Tube

- Oil Drawn Processing for Welded Tube

- Mechanical Polishing

- Pickling and Passivation

- Cleaning

- Heat Treatment

- Packaging

Oil Drawn Processing:

Oil drawn technology is the best processing technology to manufacture small-diameter stainless steel tube of precision and high purity qualities, especially meets the requirements of tubes for semiconductor and bio-pharmaceutical.

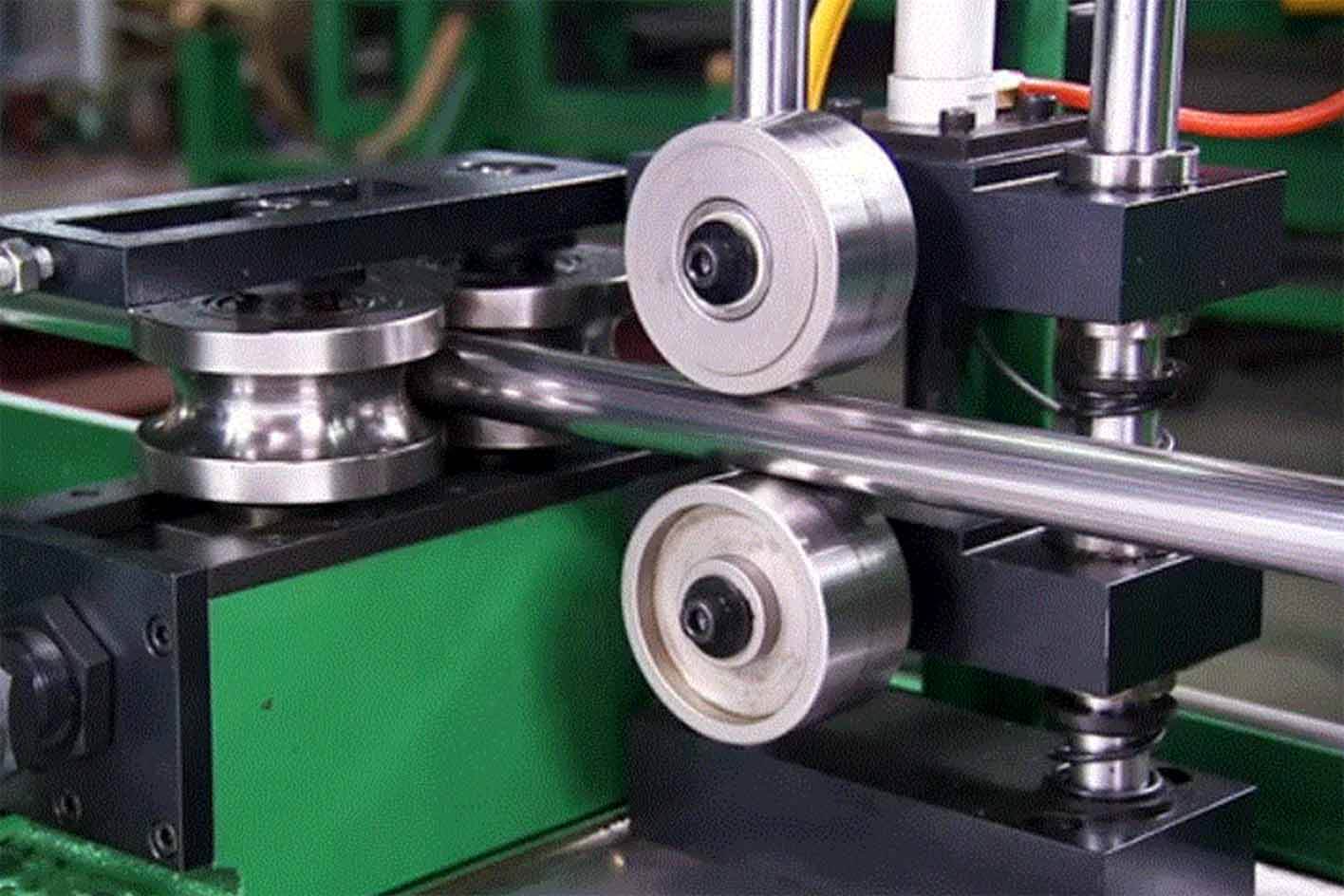

Precision Rolling:

Cold rolling is a sophisticated process for stainless steel tube manufacturing, suitable for the tubing products with less strict requirement for inner wall, widely used in food hygiene, automotive fuel rail, instrumentation and precision machinery system.

Welded Stainless Steel Tube:

Though cutting, welding, shaping, heat treatment and nondestructive testing process, high-quality stainless steel coil are precisely worked into welded stainless steel tube.According to the difference in specifications and application requirements, there are several main different welding process listed.

- TIG

- PAW

- LBW

- SAW、GTAW、GMAW、SMAW (SAW is widely used for Large-diameter welded tube)

Oil Drawn Processing for Welded Tube:

Qualified welded tubes are respectively processed by mechanical polishing, precision rolling or oil drawing, and even a combination of these technologies,which can accomplish the shadowless processing to achieve higher quality in surface and size requirements.

Mechanical polishing is divided into two processing:

Dry polishing and wet polishing, which can increase metal surface finish and reduce its roughness.Catering to clients’ requirements, both inner and outer walls can be polished.

Inner wall roughness of MP: Ra max 0.5μm

Outer wall roughness of MP: Ra max 0.8μm

Pickling and Passivation:

After polished, the stainless steel tubes need pickling and passivation treatment to form a oxide mask on surface to enhance the corrosion resistance of materials.

Cleaning:

1)The tubes will be cleaned before heat treatment mainly to remove the greasy dirt on the metal surface, so that the product can be fully restored in the heat treatment process and form a good surface condition.2)The tubes also will be cleaned again before packaging mainly to remove the greasy dirt and particulate matter on the surface of the product, achieving cleaning & operating requirements of standards and customers.

Cleaning is divided into skim cleaning, warm water cleaning, RO water cleaning, ultra-pure water cleaning(18MΩ).

Heat Treatment:

We adopt off-line heat treatment process, so the mechanical properties of materials is guaranteed.We can provide two solutions: ammonia decomposition gas protection and full hydrogen gas protection upon customers' application to cut their costs.

Packaging:

- Multi-branch into a bundle packing

- Single tube single-layer bagging

- Single tube double-layer clean bagging